How to charge or add

Freon or Refrigerant to your

Air conditioner or Heat pump.

The following material is somewhat

controversial. There are many who would like to make sure that the average

homeowner will never work on their own equipment and the industry has gone to

great lengths to get the government to regulate the use of refrigerants by the

average person. In short blame the last person that you voted for who got

elected to office. If you want to learn more about law here is a good fun place to start.

I will not discuss the legality of handling

refrigerants please take that

up with the appropriate authorities. I will simply be telling you how to know if

your system needs refrigerant and how to know how much to put in. But surf-ice

it to say that there is a correct amount of refrigerant that should be in your

system and adding any more will not make it work any better but will cause

damage.

On a recent showing of "Dateline

NBC" they set up 8 companies in the Houston Texas area. After checking

out this Trane system thoroughly they let each company look at it and every one

either added 2 pounds of R22 or said it needed 2 pounds. by the time they were

done this system had over 4 pounds (that is what they reported it could be more)

of excess refrigerant in addition to what was already in there. I can understand

the first charge but after that the head pressure on that system must have been

over 300 psi and by the end of the show the system must have been over 400 (the

compressor should have gone off on internal relief). I am guessing that is why

they chose to use a Trane or American Standard system. That just goes to show

how crooked this trade has become.

My Definitions:

Charge: The amount of

refrigerant that should be in a system to make it work when everything is

functioning.

Metering: The process of feeding refrigerant into the

evaporating portion of an air conditioning or heat pump system. You can have a

system that is properly charged and mot metering correctly. There will be no

procedure of changing the charge to make it work correctly.

Do not confuse the two.

Just about every one is familiar with a

gauge manifold, it is those two gauges that have hoses coming out that everyone

who has ever done any refrigeration work has. There are two gauges on that

manifold one for low pressure (also known as suction) one for high pressure

(also known as head). By using these gauges you can tell a lot about how your

system is working but the gauges will not tell all you need to interpret them as

well as monitor other things like the temperature of the refrigerant

lines.

The Suction pressure is a reflection of how

well the evaporator portion is picking up heat (higher) and how well the

compressor is removing it (lower). The Head pressure is a reflection of how well

the condensing coil is getting rid of the heat (lower) and how much load the

system is putting on it (higher). It may sound like a contradiction but high or

low pressure is a good thing depending on what is causing it. In general you

want the suction pressure to be as high as possible without it being caused by

an over charged condition and the head pressure to be as low as possible and

still maintain a full liquid line. High efficiency units will have higher

suction pressure and lower head pressure than an older unit depending on the

size of the coil and the airflow. If you get a steady ready of 90-100 psi

suction then you may have a compressor that is not pumping properly. It will act

like a system with an open TEV or a missing metering device.

Simply put what makes one unit more efficient than another is

bigger coils in relation to the compressor capacity. This is the dirty little

secret that no one wants to talk about.

Want a really efficient system add a second compressor that is

half the system rating (picture added soon), American Standard/Trane has one

that is a 4 ton system with 2 2 ton compressors, or a Lennox (Copeland) Two

Speed or the Bristol "Twin Single" (T/S) if you can find one. Update I have

found one and it is installed in a 5 ton Rheem system in Fort Washington

Maryland (should ring some bells).

It is

currently working in high mode only while I order the start components. When

this system is finished I will write a full report on it. If you want to buy a

System using this compressor you can order it in the "York Stealth" heat pump or

one made by Carrier and a Ground source system made by Water Furnace.

Enough of my rant now back to the subject at

hand.

From all my experience I can tell you that

an air conditioning system is correctly charged when the liquid line leaving the

condenser is full of liquid refrigerant. Adding more refrigerant will simply

waste space in the condenser and reduce efficiency and raise the head pressure.

The other issue is how well the refrigerant is being fed into the indoor coil.

Most older residential systems use capillary tubes, newer equipment uses a

drilled piece of metal called an accurator, piston or orifice, real systems use

a thermostatic expansion valve (TEV) to regulate refrigerant flow. As far as I

am concerned your system is not working correctly unless it has a thermostatic

expansion valve. The difference is that mechanical restriction works only for

certain conditions but a TEV. will deliver the right amount of refrigerant no

matter what the head pressure is and allow a perfect charge (full liquid line

without a drop more). Without this device you will have situations where you

have to add excess refrigerant (full liquid line and a filling condenser) to

raise the head pressure to push the refrigerant through the coil or the

restriction (or a lack there of) lets too much refrigerant through and you have

a liquid line that has hot gas mixed in with it and does what is called

"flooding" or "slugging" the compressor (a bad situation). In either case the

system is not working correctly and there is no "right" amount of charge that

will make it work right. If you have restricted capillaries like we have seen on

too many Rheem/Ruud units the coil will turn to a block of ice (cooling mode)

and the compressor will run very hot no matter how much refrigerant you add to

run up the head pressure. The solution to this is to replace the indoor coil

with one that has a TEV. and a larger capacity and watch the system work better

than when it was new.

I have recently added a TEV/TXV to two

system that made them work better than the day that they were installed. One was

a GE heat pump located in Annapolis Maryland that is over 20 years old. The

owners claims that it is colder now (with the TEV/TXV) than it was when it was

installed 20 years ago. The other one was a York heat pump in FT. Washington

Maryland (not the one with the Bristol Twin Single) and the owner claims that it

is colder now than it was 15 years ago when it was new.

In short adding a thermostatic expansion

valve to a system that uses and orifice/piston system can make it work for the

first time. I have since had many experiences where simply adding a TEV/TXV

makes all the difference in the world.

If you are having problems with your system

performing and you do not have a TEV/TXV then add one (if you have an orifice

system) before wasting any more time trying to make it work.

Image of Rheem/Ruud heat pump

indoor coil with thermostatic expansion valve (cooling mode). A system that

doesn't have one of these inside (cooling) and out (heating) cannot be the best

that it can possibly be.

Changing the indoor coil to one like this can bring new

life to an older malfunctioning system and it can work better than a new one

that doesn't have this feature. We have found that most cooling problems start

with a dirty or undersized indoor coil that you can't see than the outdoor unit

that you can see.

My partner Gerald has a flattened stack of

indoor coils piled to the ceiling of the garage but no replaced outdoor units.

In the last 3 years we have replaced no outdoor units but have a pile of leaking

or very dirty indoor coils. What does that tell you?

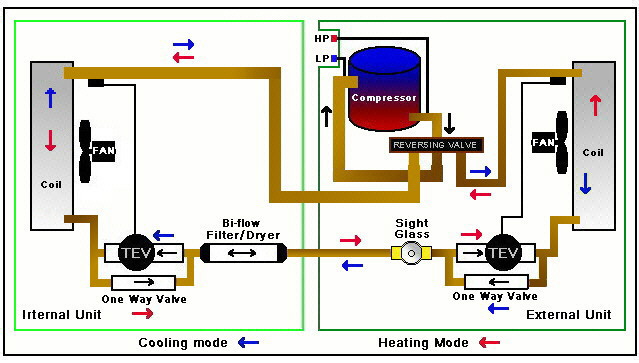

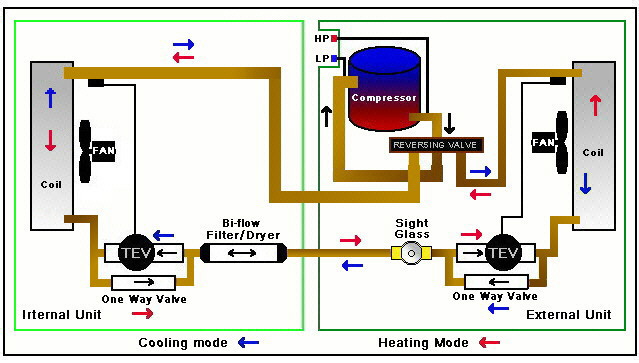

This image of a heat pump

TEV/TXV scheme was donated by 4Z5AY. The only technical change would be the

connection on the left should look like the connection on the right and there

would usually be a Bi-flow (heat pump) Filter Dryer to the left of the sight

glass not individual dryers.

The suction pressures shown are for cooling

mode. Heating mode will be lower. Head or high pressures will be similar from

heating to cooling. One of the methods of charging that I have read about that

seems to make sense when explained properly is to add charge as long as the

suction line keeps getting colder as soon as it starts to show low super heat (I

will explain that later) then there is too much refrigerant; you don't want to

flood the compressor or run the head pressure to high. What I usually do on a

system that is not a TEV/TXV. is to charge until the suction pressure gets above

55-60 psi then add more until the suction line starts to get cold. remember more

efficient systems will have higher suction pressures (80 psi is not uncommon). I

also watch my head pressure to make sure there isn't other problems (175-225 is

good depending on the condition of the outdoor coil, anything above 250 is cause

for concern). If the pressure is above 300 then there is definitely something

wrong like a very dirty coil or the system is simply overcharged. The compressor

(hermetics {piston} not scrolls or rotary) will have a ball of sweat around

where the suction line enters, what Mr. Forest Grauel calls a "happy

compressor". If the compressor becomes a ball of sweat then the system is

feeding too much refrigerant into the indoor coil. If it is dry then there is a

restriction (suction pressure will usually be low; below 40 psi cooling mode and

ice will start to grow).

Image of a sporlan sight glass

connected to a filter dryer after a liquid line solenoid valve. When the sight

glass is clear like this the system is fully charged. Adding any additional

refrigerant will just back up into the condensing coil (outdoor in cooling mode,

indoor in heating mode) If the suction pressure is still low and the refrigerant

is not feeding properly then you have a problem with the metering devices.

Adding this device is the easiest way to diagnose a problem system.

If your system has the refrigerant out for

any reason; add one of these before charging. You will thank yourself 100 times

over.

Please also See the page on icing. Which is

closely related!!!

What is "Superheat"?

You will hear and see this term all the time in

reference to refrigeration. Simply put it is the difference between the

temperature of a vapor line in relation to the temperature scale on a pressure

gauge for a particular refrigerant or how much liquid is feeding the evaporator

in relation to how fast it is being boiled off. for example (R22) if the suction

gauge reads 70 psig then the evaporating temperature is 41 degrees but if

the tubing is 51 degrees then you have 10 degrees of Superheat. A typical range

for residential air conditioning is 12-18 degrees with some error based on

extreme conditions. Once you understand Superheat you can diagnose obvious

problems. For example a system that is under charged or has a stuck (closed)

metering device will have high super heat (over 20 degrees) at the compressor

and a system that is grossly overcharged or has a dirty indoor coil can have

very low Superheat about 3-7 degrees with low suction pressure and the suction

line will be very cold.

The following conditions are for R22 in the

cooling mode and relate to indoor coil problems which contrary to human

nature we find to be 80% of the reason for poor cooling.

Human nature says that the Thermostat is

"where is all comes from" and if you can just get a new enough outdoor unit with

the right brand name everything will be ok, B.S!

My own unit is a 30 year old GE with a Trane

compressor and the original air handler. The system cools great and in the

heating mode the air comes out very hot even when it is very cold outside and

the heat pump does this without the benefit of the electric heating elements.

The point is that if I can make my 30 year old GE work this well then imagine

what I can do for your newer system or your system in general.

I will have to make a chart for outdoor coil problems. The goal

for outside is to get a full liquid line and the head pressure as low as

possible. On a newer unit 190-225 PSI of head is normal, on some older units

(20+ years) 300 PSI of head on a 90 degree day is not out of the question and be

normal. Anything higher wash the coil and consider the unit may be

overcharged.

*Warning: There are situations where due to

the conditions of you system you may have lower than normal suction pressure

and/or higher than normal head pressure. Usually lower than normal suction

pressure and any attempts to raise the suction pressure will result in

overcharging. The trick is to determine if this pressure is normal for this

system, which is usually caused by airflow problems. For example some systems

with low air flow, 50-55 PSI is normal. The secret to being a good mechanic it

to determine if this is a normal pressure and leave it alone.

Normal Superheat

Normal suction pressure |

Suction pressure 65-80 psi

8-15 degrees superheat. depending on

size of indoor coil, air flow and condition.* |

Head pressure 190-225 on newer units 300 not out of the question on an

older unit on a 90 degree day. |

Full liquid line, sight glass will be clear, compressor will draw near

rated current (NEVER charge by current

draw). |

| Low super heat low suction pressure |

Dirty indoor coil, no or poor air flow. |

Coil will ice up quickly. One of the most common problems! |

3-7 degrees superheat suction pressure 35-40 psi Suction line will

freeze out to to the compressor. Compressor will be ruined because of oil

dilution. |

| Low super heat higher than normal suction pressure |

Over feeding refrigerant or overcharged |

If overfeeding head pressure will be slightly lower than normal if

overcharged head pressure can be sky high. |

65-80 psi 5-10 degrees superheat. |

| High superheat lower than normal suction

pressure. |

Refrigerant not feeding properly. |

Could be slightly undercharged or a problem with the metering device.

If overcharged head pressure can be sky high. |

40-60 psi suction. 18-25 degrees superheat. |

| High superheat very low suction

pressure. |

Refrigerant not feeding at all |

Could be almost out of refrigerant. compressor will overheat and be

destroyed. |

20-40 psi

Compressor will get very hot and shut off on internal

protection. |

| Low super heat high suction pressure. Lower than normal head

pressure. |

Compressor is not pumping properly. Or possibly metering device is

missing or stuck open. A heat pump check valve (indoor coil) is blown. |

Replace compressor. Check for open metering device or blown check

valve. |

Compressor will be flooded.

80-100 psi. Pressures will equalize

almost instantly |

This page will be continued later:

Scott Meenen can be reached at 301-591-1646

Click here to

return or go to the home page:

For a list of all the pages on

this site go to the site map.

Please

bookmark for future reference

Written By: Scott Meenen

N3SJH of

G&S MECHANICAL SERVICES.

Serving Maryland, DC, and Northern

Virginia.

Contact us

Email us at: mailto:jsmeenen@toad.net?subject=charge

response from webpage

Specializing in Mechanical, Controls and Electrical Modifications

Of

Heating, Air

conditioning, Refrigeration, Cold storage,

Ice Production and Food

preservation.

Anything having to do with Heat and Energy.

We service and repair the following brands:

American Standard, Amana, Arco, Arco-Air, Bryant, Carrier,

Coleman Evcon, Comfortmaker, Day/Night/Payne, Dunham-Bush, Fedders, Fredrich,

Goodman, General Electric, Hotpoint, Heil, Intertherm, Janitrol, Kenmore, Lennox

(Armstrong, Johnson Air-Ease), Miller, Modine, Nordyne, Rheem/Ruud, Sears,

Stewart Warner, Trane, Williams, White-Westinghouse, Whirlpool, Weil Mclain,

York, (Frasier Johnson/Borg Warner) and others.

MARYLAND DC. VIRGINIA

AREA

BACK TO

TOP